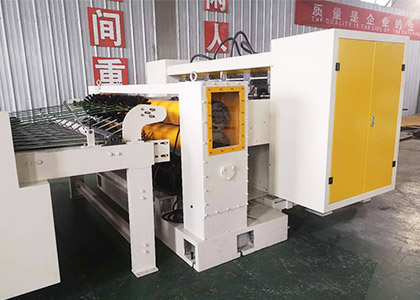

HSF-150-2 Series automatic (2 ply) single face corrugated cardboard production line

Machine list and main specification

| Model | Equipment name | QTY | Remark |

| ZJ-V6 | Hydraulic shaftless mill roll stand | 2 | Spindle ¢ 270mm, hyperbolic heavy rocker, toothed chuck , multi-point brake, hydraulic drive lifting, panning left and right on the middle. Rail length 6000mm,trolley used 10mm plate welding. |

| Paper trolley | 4 | ||

| RG-900 | preheat cylinder | 2 | roller ¢900mm,including pressure container certificate. Electric adjustment wrap angle。Wrap angle can adjust the paper preheat area in the range of 360°. |

| SF-320C | Fingerless type single facer | 1 | Corrugated main roller ¢320mm,material with 48CrMo alloy steel, tungsten carbide dealing is optioanl, Tile roll modular group lifting transfer. Airbag ballasting structure,import main bearing,PLC automatic control glue,HMI touch screen,Breaks automatic parking relief,steam heating way. |

| ZDF | Conveyor bridge | 1 | Independent frequency motor drive lifting, transmission。Main beam is connected with the 20th channel, 16-beam, No. 63 angles, columns, etc. Both sides of the security fence, the word pedals, ladders. |

| NC-150 | Computerized slitter and cut off and stacker | 1 | AC servo control spiral knife structure,Touch screen display. Collect paper machine adopting a classification adjustable count output cardboard,The maximum length of stacked is 1.3 meters. pull paper feed and transverse motor is all frequency speed control,NC thin knife slitting 5 group blades。Spiral knife Crosscutting. |

Parameters requirements in production line

| note | heating surface temperature should reach 172 ℃ | |||

| Paper grade | not less than grade B | |||

| Paper moisture content | 11%±2% | |||

| Facial tissue | 100—250g/m2 | |||

| Core paper | 100–180g/m2 | |||

| 9 | Flute combination | A 、C、 B、 E(Or a choice by the customer) | ||

| 10 | Steam requirment | maximum pressure 1.2MPA | Steam consumption: about 500Kg/Hr | Common pressure:0.8-1.1Mpa |

| 11 | Electricity demand | AC380V 50Hz 3PH | Installed capacity≈90KW | |

| 13 | space | ≈30m×11m×5m(Specific length of foundation Figure prevail) | ||

Customer-owned section

| 1、 steam heating system:proposal with 500Kg / Hr of a steam boiler pressure:1.25Mpa steam pipeline。 |

| 2、 air compressed machine、air pipeline、glue conveying pipe。 |

| 3、 power supply、wires connected to the operation panel and line pipe。 |

| 4、 water sources、water pipelines、buckets and so on。 |

| 5、 Water, electricity, gas flush mounting civil foundation。 |

| 6、 Test with the base paper、corn starch (potato)、Industrial use caustic soda、borax and other material。 |

| 7、 Oil equipment、lubricating oil、hydraulic oil、lubricating grease。 |

| 8、 installation、commissioning of food, accommodation。And provide installers with the installation |

Machine size and speed

| MODEL | HSF-1400-150-2 | HSF-1600-150-2 | HSF-1800-150-2 | HSF-2000-150-2 | HSF-2200-150-2 | HSF-2500-150-2 |

| SIZE(MM) | 1400 | 1600 | 1800 | 2000 | 2200 | 2500 |

| SPEED | 90-150M/MINUTE | |||||