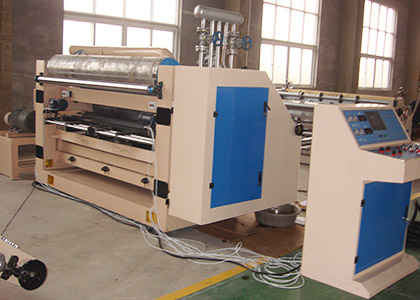

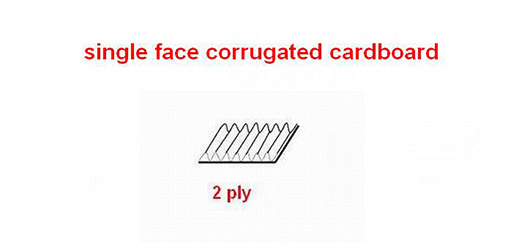

SF-100-2 Series (2 ply) single face corrugated cardboard production line

Machine list and main specification

| Model | Equipment name | QTY | Remark |

| ZJ-V6

|

Hydraulic shaftless mill roll stand | 1 | Spindle ¢ 270mm, hyperbolic heavy rocker, toothed chuck , multi-point brake, hydraulic drive lifting, panning left and right on the middle. Rail length 6000mm,trolley used 10mm plate welding. |

| Paper trolley | 2 | ||

| SF-280S | Fingerless type single facer | 1 | Corrugated main roller ¢280mm,material with 48CrMo alloy steel, with heat treatment for hardness HRC58-60, vacuum absorb fingerless single facer. With Roller temperature controller, automatic glue circulation. Motorized glue width setting, separately gear box drive. |

| NC | Rotary sheet cutter | 1 | Adopt variable frequency motor to adjust the speed. Servo control make the cutting length more precision. (error±1.5mm) PLC touch screen set the cutting size, save order memory |

Parameters requirements in production line

| note | heating surface temperature should reach 172 ℃ | |||

| Paper grade | not less than grade B | |||

| Paper moisture content | 11%±2% | |||

| Facial tissue | 100—250g/m2 | |||

| Core paper | 100–180g/m2 | |||

| 9 | Flute combination | A 、C、 B、 E(Or a choice by the customer) | ||

| 10 | Steam requirment | maximum pressure 1.2MPA | Steam consumption: about 500Kg/Hr | Common pressure:0.8-1.1Mpa |

| 11 | Electricity demand | AC380V 50Hz 3PH | Installed capacity≈30KW | |

| 13 | space | ≈15m×11m×5m(Specific length of foundation Figure prevail) | ||

Customer-owned section

| 1、 steam heating system:proposal with 500Kg / Hr of a steam boiler pressure:1.25Mpa steam pipeline. |

| 2、 air compressed machine、air pipeline、glue conveying pipe. |

| 3、 power supply、wires connected to the operation panel and line pipe. |

| 4、 water sources、water pipelines、buckets and so on. |

| 5、 Water, electricity, gas flush mounting civil foundation. |

| 6、 Test with the base paper、corn starch (potato)、Industrial use caustic soda、borax and other material. |

| 7、 Oil equipment、lubricating oil、hydraulic oil、lubricating grease. |

| 8、 installation、commissioning of food, accommodation. And provide installers with the installation. |

Machine size and speed

| MODEL | SF-1400-100-2 | SF-1600-10-2 | SF-1800-100-2 | SF-2000-100-2 | SF-2200-100-2 |

| SIZE(MM) | 1400 | 1600 | 1800 | 2000 | 2200 |

| SPEED | 40-70M/MINUTE | ||||