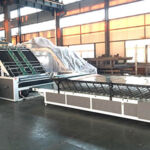

BZJ-L series automatic flute laminator machine

MACHINE DESCRIPTION

1.Suction floating feeding paper, accurate running balance. Photoelectric control to avoid single – sheet walking. The machine adopts the prepush position : the paper and corrugated fit error range is + / – 1.5mm

2.synchronous belt drive: imported synchronous belt, maintenance-free, accurate, stable and noiseless.

MACHINE FUNCTION

1. The machine adopts unique pressure spring front gauge design, which effectively reduces mechanical failure rate and ensures accurate positioning with intelligent control.

2. The machine adopts frequency conversion to regulate speed. PLC centralized control, module conversion, operation control standard

3.Double servo control is adopted to realize the timeliness and accuracy of the base paper to the front gauge, so as to ensure the accuracy of the machine under the operating condition

4. After balancing treatment and testing, the steel roller, coupled with the tightening assembly process, effectively improves the mechanical stability. In addition, when the main transmission is driven by the timing belt, the bottom paper part directly absorbs the air and delivers the paper, effectively improving the operating accuracy and speed of the machine

5.Adopt the page control system to automatically recycle the glue, which greatly reduces the labor intensity.

6.The machine adopts all ISO9001 standard inspection of materials, with high quality and solid durability. Key parts such as bearings are imported

7.Independently develop a powerful FEIDA paper with precoded paper device to reduce downtime and improve work efficiency

8.The machine is suitable for 150-450gsm paper, A B C D E F wave and three and five layers cardboard (the maximum thickness is less than 10mm)

MACHINE TECHNICAL PARAMETER

| Specifications | BZJ-1300L | BZJ-1450L | BZJ-1650L |

| Maximum Size | 1400*1300mm | 1400*1450mm | 1400*1650mm |

| Minimum Size | 400mm*400mm | 400mm*400mm | 400mm*400mm |

| Max Design Speed | 100pics/min | 100pics/min | 100pics/min |

| Power | 15kw | 15kw | 15kw |

| Dimensions(mm) | 12000*2250*2655 | 12000*2400*2655 | 12000*2550*2655 |

| The Total Weight | 4T | 4.5T | 4.8T |

| The Paper Requirements | Face paper: 150 g / ㎡-450 g / ㎡ |

Facer paper: 200 g / ㎡-450 g / ㎡ |

Face paper : 200 g / ㎡-450 g / ㎡ |

| Base paper: minimum weight 300 g / ㎡- 800 g / ㎡ |

Base paper: minimum weight 300 g / ㎡- 800 g / ㎡ |

Base paper: minimum weight 300 g / ㎡- 800 g / ㎡ |

|

| the biggest thickness: 10 mm | the biggest thickness: 10 mm | the biggest thickness: 10mm |

MAIN COMPONENTS BRAND

| Components Name | Brand |

| Surface Feed Paper Using FEIDA | Beijing |

| Proximity Sensor | OMRON |

| Bearing | Japan NSK |

| PLC | Japan Panasonic |

| Frequency Converter | TAIDA |

| Touch LCD | TAIDA |

| Synchronous Belt | The United States gates |

| Flattening Conveyor Belt | Italy |

| The Chain | Japan |

| Servo Motor | INVT |

| Main Motor | Fierce cow |

| Reduction Motor | Taiwan |

| Suction Belt | Japan’s Nuttin |

| Contactor | SCHNEIDER |

| Button | Delixi |

| Liquid Level Relay | Taiwan Pine Ling |

| Vacuum Pump | Taiwan |

| Vortex Pump | Zhejiang Dense |