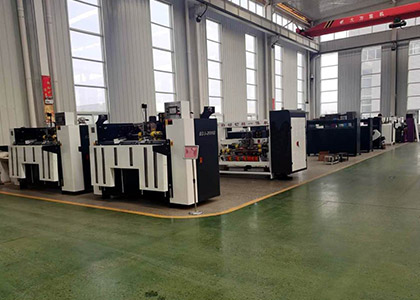

YN-BDJ-B series semi-auto stitching machine

MAIN PURCHASED PART

| SIN | NAME | BRAND | NOTE |

| 01 | Stitching Head Servo Motor | Japan Mitsubishi | 1 Set |

| 02 | Feeding Servo Motor | Japan Mitsubishi | 1 Set |

| 03 | PLC | Japan Omron | 1 Set |

| 04 | Contactor/Circuit Breaker | German Siemens | |

| 05 | Photoelectric Switch/Proximity Switch | Japan Omron | |

| 06 | Stitching Head Gear Reducer | Taiwan Li-Ming | |

| 07 | Touch Screen | Taiwan WEINVIEW | |

| 08 | Intermediate Relay | France Schneider | |

| 09 | Nail Head Entire Group | Taiwan | |

| 10 | Blade | Tungsten Steel Alloy | Wear-Resistant |

| 11 | Die Block | Tungsten Steel Alloy | Corrosion-Resistant |

| 12 | Air Cylinder/Solenoid Valve | Taiwan Airtac |

MAIN FUNCTION

1.Mitsubishi dual servo drive, precision, mechanical transmission part reduction, can effectively reduce the failure rate of machinery.

2. WEINVIEW touch screen operation, parameter (nail distance, nail number, nail type, backboard) conversion is convenient and fast.

3. The whole control system adopts Japanese omron PLC control system.

4. Rear electric baffle, using stepper motor drive, accurate size, more convenient and fast size change.

5. The full contactor in the control box adopts Siemens brand.

6. All relay adopts French schneider brand.

7. Photoelectric and proximity switch adopts Japanese omron brand.

8. Bottom die, blade made of Japanese tungsten steel (wear resistant).

9. the whole group of nail head made of special steel, computer gong precision processing.

10.can nail single nail /, double nail //, strengthen the nail (// // / both ends are double nails in the middle part of a single nail) completed in one time, can be suitable for different customers to nail different requirements.

11.changing carton size and adjusting carton stitching distance can be completed in only one minute, greatly saving time and convenient operation.

12.front end of the paper feed automatic count, paper feed table with photoelectric induction device, automatic rise when the paper feed.

13. there is automatic counting function in the back section. The finished product sheets can be folded and sent to the end of the transport machine according to the set quantity (1-99), which is convenient for packing and binding.

14. Mechanical speed: 600 nails/min.

15. Nail distance :30-120mm arbitrary adjustable.

16. Paper pressure rubber wheel gap electric adjustment.

17. Effective height of lifting ::900mm.

18. Machine size: main machine 2.8×1.7×1.8m.

19. Machine weight :2T.

20.Machine order type adjustment, can store 1000 orders.

21. Protection function of electrical isolation transformer;Automatic wire feeding system, 20KG flat wire, saving time.

22. front and rear two-way baffle configuration, can order lidless cartons and small cartons, color boxes.

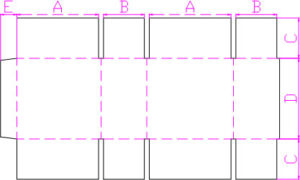

MACHINE PARAMETER

| Max size(A+B)X2 | 3750mm | Minimum length A | 250 mm |

| minimum size(A+B)X2 | 800mm | Maximum height D | 2000 mm |

| Max size(C+D+C) | 3000mm | Minimum height D | 100 mm |

| Minimum size(C+D+C) | 250mm | Maximum tongue width E | 40 mm |

| Minimum cover C | 15mm | Maximum feed height | 900mm |

| Max cover C | 520mm | Mechanical width | 2850 mm |

| Maximum width B | 770 mm | Machine weight(T) | 2 |

| Minimum width B | 150 mm | Mechanical speed (nail/min) | 600 |

| Maximum length A | 1105mm | DingShu | 2-99 |