YN-SQDJ-2200 series automatic double pieces carton box stitcher machine

MAIN PURCHASED PART

| SIN | NAME | BRAND | NOTE |

| 01 | Lead edge feeder feeding servo motor | Japan Yaskawa | 2 set |

| 02 | Bottom Stitching Head Servo Motor | Japan Yaskawa | 1 Set |

| 03 | Bottom stitching head Feeding Servo Motor | Japan Yaskawa | 1 Set |

| 04 | Correction servo motor | Japan Yaskawa | 1 Set |

| 05 | Paperboard receive servo motor | Japan Yaskawa | 1 Set |

| 06 | Baffle servo motor | Japan Mitsubishi | 1 Set |

| 07 | Top Stitching Head Servo Motor | Japan Mitsubishi | 1 Set |

| 08 | Top stitching head Feeding Servo Motor | Japan Mitsubishi | 1 Set |

| 09 | PLC | Japan Omron | 1 Set |

| 10 | Stitching Head Gear Reducer | Taiwan Li-Ming | 5 sets |

| 11 | AC drive | France Schneider | |

| 12 | Contactor/Circuit Breaker | Japan Mitsubishi | |

| 13 | PLC/ Photoelectric Switch/Proximity Switch | Japan Omron | |

| 14 | Intermediate Relay | France Schneider | |

| 15 | Touch Screen | Taiwan WEINVIEW | |

| 16 | Blade | Tungsten Steel Alloy | Wear-Resistant |

| 17 | Die Block | Tungsten Steel Alloy | Corrosion-Resistant |

MAIN FUNCTION

1. The machine adopts Japan Yaskawa, Mitsubishi brand servo drive, precise and accurate, reduce the mechanical transmission part which can reduce the failure rate of machinery.

2. The contactor of the whole machine adopts Japanese Mitsubishi brand

3. The relay adopts Schneider brand from France, the circuit breaker adopts Mitsubishi brand from Japan, the photoelectric and proximity switch adopts Omron brand from Japan; Air Cylinder and solenoid valve adopt Taiwan Yadecke brand;

4, the whole group of nails are made of special steel, CNC precision machining;

5. Bottom die, blade made of Japan tungsten steel (wear-resisting);

6. carton with lid & carton without lid can be nailed (if stitch carton without lid, please specify when order machinery)

7. The nail head is powered by Japan Yaskawa servo motor, mechanical speed: 700-800 nails/min;

8. Four mouth nails, about 60 pieces per minute;

9. The whole machine adopts nine servo drive motor systems;

10, one machine with dual-purpose: single-piece carton stitch, two-piece carton stitch, irregular carton stitch.

11. The machine Can nail reinforcing nails, single nails, double row nails, one time finish

12. Stacking unit: automatically counts output, and the finished cartons are sent out for easy strapping;

13. This machine touch screen display fault instructions.

14. The whole machine electrical isolation voltage transformer protection device, better protection of the whole computer electrical service life.

15. Automatic wire feeding system, load 20KG, save time.

16, suitable for small and medium carton box factory, speed fast and labor saving;

17. suitable work for 3 ply/5ply corrugated cardboard(7 ply customerized)

INTRODUCTION

The Double pieces automatic carton box stitching machine consists of six parts: lead edge vacuum feeder part, paperboard receiving part, folding part, box stitching part, counting output part and electric control part. PLC control , touch screen for data input and servo motor control of the stitching action, simple and reliable operation. Automatic feeding, automatic folding, automatic correction, automatic stitching, automatic counting, automatic stacking output. Advanced technology and reliable quality.

A. Feeding unit

1, the main motor adopts frequency conversion speed regulation, the system is noiseless, speed regulation is flexible and stable.

2. Adopt the Double servo feeding , stable, efficient and accurate adjustment.

3, the front feeding department can be electrically adjusted, suitable for the various size cardboard, convenient and fast.

4. Equipped with side flapping device to ensure that the paper feed is precision

B. Paperboard received unit

The paperboard received unit is the Buffer connection between the first stitching and the folding unit. After first stitching, paperboard received unit send the paperboard to folding unit instantly.

C folding unit

1, Frequency conversion speed regulation. Linkage movement with feeder unit

2, Adopt the imported porous tape to delivery the cardboard, automatic folding, vacuum transfer, avoid the heavy box, coated box, polishing box and other variety of cardboard from the skew and slip stacking, so that the machine is more stable and efficient

D.correction unit

1. The machine have a correction device which install between the folding part and the second stitching machine. Before stitching the box, the correction device will flap and reshaping the fold carton. make sure that there is no scissors on the carton.

2. Servo motor is used in the correction unit.

E stitching unit

1. The stitching head is made of special material, which is wear-resistant and not easy to be damaged.

2. The stitching head drive by the servo motor, stable and accurate speed.

3. Adopt the Two large reel which can load 20kg stitching wire , automatic wire feeding device which can reduce the wire change times and improve the production efficiency.

4. The machine can work single piece nail, double piece nail, reinforcing nail and head and tail nail and so on

5. The stitching speed can reach 700 nails per minute

F, counting, stacking and output unit

After stitching the box, the counting and stacking unit will be sent out the box.

Main parameters:

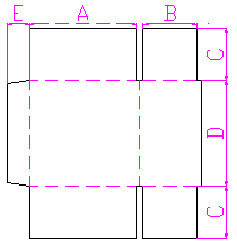

| PARAMETER | SQDJ-2200 |

| MAX(A+B) | 1100 |

| MIN(A+B) | 650 |

| MAX(C+D+C) | 860 |

| MIN(C+D+C) | 360 |

| MIN C | 25 |

| MAX C | 500 |

| MAX B | 500 |

| MIN B | 200 |

| MAX A | 900 |

| MIN A | 450 |

| MAX D | 700 |

| MIN D | 110 |

| E | 30-35 |

| NAIL DISTANCE(mm) | 30-120(HIGH SPEED) |

| NAIL QUANTITY | 2-99 |

| MECHNICAL SPEED(NAIL/MINUTE) | 600-700 |

| WEIGHT(T) | 12T |