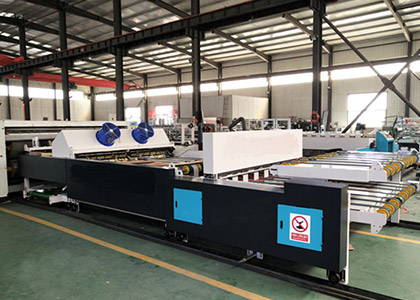

YN-DMJ Series Automatic Cardboard Stripping & Counting Stacker

Main instruction

This equipment is a practical and new type of high-efficiency auxiliary equipment for circular die-cutting and printing presses with die-cutting. Its functions include paper receiving mechanism, vibration cleaning mechanism, automatic alignment mechanism and automatic output of cardboard points.

Man-machine interface operation, digital display speed control, microcomputer display, simple, fast, reliable and precise control mode, automatic paper receiving, automatic counting, automatic stacking output, and average stacking speed of 240 sheets/minute.

The paper receiving mechanism includes a driving shaft fixed on the frame and a conveying wheel linked with the driving shaft through a belt. A waste-type high-strength conveying belt is superimposed on the conveying wheel. The output of the conveying wheel is equipped with an automatic alignment mechanism and an automatic alignment mechanism A cardboard transfer and output mechanism is provided directly below the cardboard.

This machine has a small footprint, low cost, low energy consumption, neat stacking, long service life and easy operation. High efficiency, energy saving and environmental protection are our highest pursuits.

1.The configurations:

1). The automatic stacking machine outputs neatly.

2). The main motor of the technical department is frequency-adjustable, the speed is adjustable, and the startup is stable and reliable.

3). The cartons are transported by belts, stacked neatly, and the speed is 0-130m/min.

4). Counting and pushing adopt pneumatic method, PLC electric control, reliable, accurate and fast action.

5). It adopts PLC to become a controller and touch screen digital control, simple operation, reliable action, input data without stopping, and automatic counting.

6). Automatic turning board, can directly convey the cardboard to the automatic box gluer and automatic nail box machine, reducing labor.

2. Origin of main parts

1). The main engine bearing is mainly Harbin, and the auxiliary bearing is LK.

2). The main engine belt adopts German Siegling.

3). The screws and nuts of the whole machine adopt the national standard 8.8 level.

4). The pneumatic original parts adopt the brand of Zhejiang Somai. (Cylinder, solenoid valve, connector).

3. Producing area of main electrical parts

1). Touch screen (Taiwan Weilun).

2). PLC main control (Taiwan Yonghong).

3). Frequency converter (domestic Jiale).

4). button switch (Zhejiang Chint).

5). AC contactor (Zhejiang Chint).

6). Intermediate relay (Japan Omron).

7). Counting photoelectric (Taiwan Yangming).

8). Switching power supply (Taiwan Mingwei).

9). Circuit breaker (Zhejiang Chint).

10). Main and auxiliary motors (made in Jiangsu).

stacker-machine-300x214.jpg)